Read Our Full History

To purchase a copy of Algonquin Harvest: The History of the McRae Lumber Company please contact us at information@mcraelumber.ca

The History of McRae Lumber

A Legacy We’re Proud to Continue

To purchase a copy of Algonquin Harvest: The History of the McRae Lumber Company please contact us at information@mcraelumber.ca

The McRae Lumber Company was founded in 1922 when JSL McRae purchased the Airy Mill from the Mickle and Dyment Lumber Company. Although this marked the official start of the company, the family lumbering tradition extends back two generations further.

JSL’s father John Duncan owned a sawmill at the fourth chute of the Bonnechere River in Eganville from 1904 to 1911. The lumbering experience was also present through John Duncan’s wife, Isabella Campbell McRae. Isabella’s father John Campbell was Manager of John Egan’s Bonnechere operations and also had a timber berth near Golden Lake.

In 1922, JSL McRae purchase the Airy Mill from the Mickle and Dyment Lumber Company of Gravenhurst. The mill generally ran from about the 14th of April until the endo of October or until all the logs went through the mill. The mill operated until 1933 when it burnt, while shut down for the season.

The bush operations during the time of the Airy Mill were characterized by labour-intensive hard work on long cold winter days. A typical bush camp consisted of 100 men and 30 horses. They would work together to fell, skid and haul the timber from the forest to log dumps on or beside the lakes, where they would await the spring thaw.

McRae usually employed 12-14 cutting gangs of 5 men each who worked from September till Christmas or shortly thereafter. Each of the logg-making crews was comprised of two log makers, one trail cutter, one skidway man and one temaster.

The average cutting gang could cut and skid about 40 hardwood logs or 60 softwood logs a day. The logs would be piled on skidways, sitting adjacent to the haul road with each skidway holding up to 250 logs. The log haul began after Christmas, as soon as the haul road was ready. To prepare the road, teams had to build up lake ice to at least 20 inches, plow the road and ice the ruts for the sleigh runners to glide on. The average hauling distance was about 2.5 miles, with each team doing three trips and moving about 300 logs.

Softwood logs were dumped on the lake and boomed together, whie hardwood logs were usually piled on land beside the lake and then boomed or cribbed together for their journey to the mill. The drive by water consisted of towing the logs across lakes with cadge cribs or an alligator (a flat-bottomed boat, powered by steam that could also winch itself across land) and running the logs through log chutes that bypassed sets of rapids on rivers.

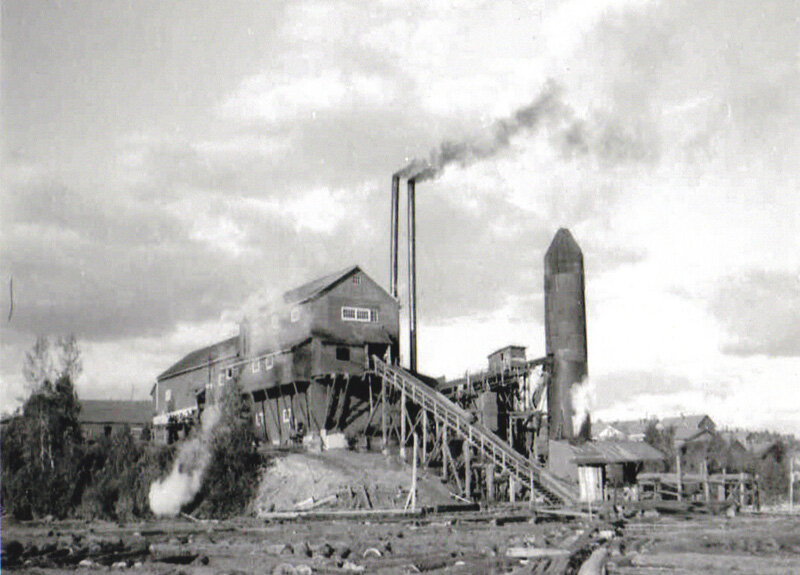

The mill at Airy was a large mill, built primarily for softwood. It had three boilers, burning sawdust and mill refuse that developed 300 HP to power the mill. Inside, the mill was two-sided, meaning it had one big band saw and a pony band saw. The average daily output was around 50,000 board feet or between 6 and 7 million board feet per year.

The Airy Mill on the shore of Galeairy Lake with Anchor Island in the background.

View of the mill from the lake showing the jackladder that carried the logs up to the bandsaw.

The man kneeling near the Barrienger brake is controlling the descent of the loaded sleigh in the background.

After the Airy Mill burned down, there was essentially nothing to salvage. JSL put together enough money from insurance, lumber that was saved from the fire and a loan from the Bank of Montreal to build the Lake of Two Rivers Mill.

Bush camps remained essentially the same as the those that served the Airy Mill. With the men still living and working the entire winter in the camp. Some years the men would walk out to see their families at Christmas if the camps were located close enough.

The device in the photograph is called a Barrienger brake. It consisted of a low steel frame with a number of in-line steel wheels through which a steel cable was woven. The brake was then anchored to a tree at the top of a steep hill and attached to a loaded sleigh. When operated, the brake controlled the decent of the loaded sleigh down the treacherous hill.

In the mid 1930s, the bush operations underwent a dramatic transformation with the beginnings of mechanization. The introduction of tractors and trucks to replace horses on the skid and haul resulted in significant changes. Although the new methods took time to get used to, they proved to be more efficient.

The mill was situated right in the centre of the cutting limits with areas both north and south of the railway destined for cutting. The position of the railroad was advantageous as it allowed for logs to be transported to the mill from some of the camps that were located near the line.

The Two Rivers Mill was smaller than the Airy mill as it was a one sided mill. Meaning it only had one bandsaw headrig along with a flatbead resaw and edger. This mill was the first to have a hot pond with steam from the mill heating the water. Frozen logs were put into the pond, where they thawed and allowed the mill to cut year round. The mill cut about 30,000 to 40,000 board feet of hardwood and 40,000 to 45,000 board feet of softwood per shift.

In 1942, the mill was moved to Hay Lake to access the timber limits in Clyde, Sproule, Bruton and Bower Townships. This period saw the beginning of the movement to a sustained yield from the forest. The company hired a professional forester to setup the cutting plan required by the government.

The main cut was divided about evenly between sugar maple and yellow birch, with the remaining ten percent being made up of spruce, hemlock, white pine and beech. Log cutting began when the sawmill was shut down, usually about the middle of October. Work in the bush was still very focused on manual labour and horses still played a prominent part skidding the logs out of the bush. Trucks were used primarily to pull the haul sleighs and starting about 1950 were used to ship lumber.

To increase efficiency in both the mill yard and in the bush two Skyline Power Jammers (shown in the photo above) were purchased. These machines were much faster, piled higher and were much safer to use. The power jammer needed five men to run and obtained its power from an eight-cylinder Dodge engine.

Between Hay Lake and Mink Lake there is a height of land. The hills between these lakes presented an obstacle, that even with trucks, made the haul to Hay Lake far too difficult. So in 1952 the mill was moved to Mink Lake. In the forests surrounding Mink Lake the Company continued to apply the new methods of sustainable yield cutting as promoted by their forester Felix Tomaszewski.

One of the biggest changes at Mink Lake was the transition to all-weather gravel roads. This meant that winter was no longer the only season where timber hauling could occur. This led to another change as gravel roads made commuting in and out of the bush camps for the weekend a possibility and so ended the tradition of men walking into the bush in the fall and not returning until the spring.

With the cut complete in Southern Bruton Township the mill was moved and rebuilt on Whitefish Lake. Although initially very little had changed since the days of the Airy Mill as time passed the Rock Lake Mill underwent a number of changes.

The drive toward mechanization and the movement toward a scientifically proven sustainable harvest were the two most important on-going developments. The time at Rock Lake saw the origins of new products such as wood chips and new machines such as hydraulic loaders and skidders. The implementation of these new machines signaled the end of an era. No longer were horses required in the bush.

“Old timers claim that the disappearance of the horses changed the camps more than anything else in lumbering history.”

The last horses worked in the bush at Lemon Lake in 1962.

1974 and 1975 were tumultuous years as they saw the creation of the Algonquin Park Master Plan and the Algonquin Forestry Authority, respectively. The McRae Lumber Company, under Donald McRae, worked proactively with the Ministry of Natural Resources and AFA to ensure a future for the forest industry in Algonquin Park that revolved around sound science, sustainable harvests and ecological integrity.

The Rock Lake Mill was situated on the old OA&PS Railway line about 32 kms south of Highway 60 inside Algonquin Park.

The boardway; where lumber was sorted and piled

When the Rock Lake Mill closed in 1979 it was the last lumber mill to have operated inside Algonquin Park. Although the company now operates in the nearby town of Whitney, the reliance on Algonquin Park timber is still very strong.

Today, the McRae Lumber Company site consists of three main processing operations: a slashing-chipper line to handle the large volumes of cull wood resulting from a selectively harvested forest, a small scragg mill to process the smaller lower quality wood that is also inherent with selectively marked trees harvested in tree-length form, and a band mill that processes the smaller volume but higher quality sawlogs.

The High-Grade Band Mill was built in 1979.